In the world of water bottles, three materials are king: plastic, stainless steel, and glass. While there are strong arguments for use of each of them, when it comes to finding the most eco-friendly option, glass towers above the competition as the clear winner.

When handled properly, glass has environmentally friendly benefits at every stage of its life cycle. Unlike plastic or stainless steel, the production of glass does not cause harmful by-products and the materials needed to make glass are much more readily available and easy to obtain. Plastic bottles are manufactured with the use of huge amounts of increasingly expensive petroleum products, a material which is almost the direct opposite of glass in that it is environmentally harmful at every stage of its production.

Similarly, the production of stainless steel relies on the mining of chromium ore – massive operations undertaken by mining companies which literally carve the earth asunder. Worse still, chromium ore mining operations can expose workers a substantially increased risk of developing cancer. The acquisition of this ore is only the beginning of the harmful impact stainless steel production has on the planet, as the process of refining it is responsible for huge amounts of pollution.

A Tried and True Solution

Given what we know about the manufacturing of plastic and stainless steel bottles, it would be reasonable to expect glass bottles to have an environmentally devastating production process. While some other materials are involved in the production of modern glass, the main ingredient in glass remains silica – or plain old sand. Something which is plentiful and abundant across the whole planet – lying freely on its surface, requiring no channels carved with explosives to be further stripped and mined, and never necessitating drilling deep to find oil pockets.

The only considerable environmental impact from glass production comes in the form of atmospheric pollution, the result of furnaces used to heat the glass. Even this atmospheric pollution is negligible compared to the by-products of plastic and stainless steel production.

An Endless Cycle

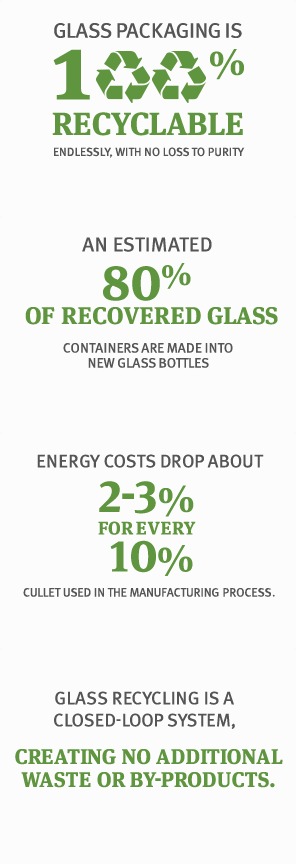

Interestingly enough, we have now reached a point where many glass manufacturers have little need to get raw materials at all. The massive success of glass recycling programs now means that huge amounts of the glass produced today is sourced from recycled glass, which can simply be melted down and reused. This process saves massive amounts of energy, reduces materials cost, and prevents waste from piling up in our cities and landfills.

While similar recycling initiatives exist for plastic and even metals, the nature of glass allows for it to be infinitely recyclable – it never loses quality, strength, or durability no matter how many times it is reused.

Combined with its low-impact manufacturing process, this truly seals the deal for glass as the healthiest option for our planet’s sake! New glass can be produced with relatively little expenditure or pollution at any time, while the existing glass reserves can be endlessly recycled into brand-new bottles.

Next time you pick up a water bottle, think of the planet! Go green, go glass, pick up a Glasstic! Want to learn more about the benefits of glass? Check out the Hydration Anywhere feature “Why You Want a Glass Water Bottle” over at my blog.

Guest post by Jacob Hatch. Jacob is the author of the blog Hydration Anywhere. Formed with the goal of providing a dedicated resource for all things related to staying hydrated – with everything from health tips to environmental awareness to looking at the latest water-related products, the blog is an ever-growing resource. When not writing, Jacob spends most of his time riding his bike, checking out new restaurants, and slappin’ da bass.

Follow Hydration Anywhere on

Facebook

Twitter

Pinterest

Google+

Glass Stats image via Glass Packaging Institute

Glasstic image via Hydration Anywhere